ELECTROFUSION WELDING MACHINE

UNIVERSAL ELECTROFUSION WELDING MACHINE

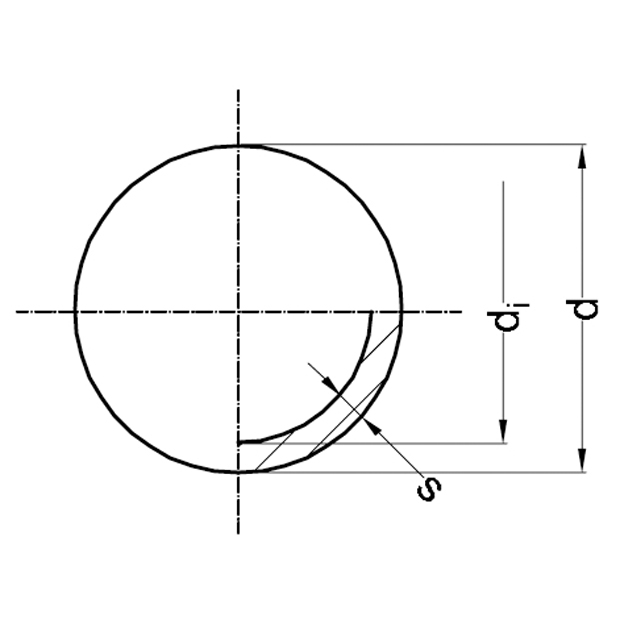

- For diameter d20-d315.

- Robust plastic housing IP 54, insulation class II.

- Mains cable 5 m/4 m fusion cable with socket contacts 4,0 mm.

- Reader wand for barcode reading.

- Welding voltage up to 48 V DC.

Delivered in practical aluminium transport box.

| Article | kg |

|---|---|

| 5150 31011 | 11,000 |